With rising concerns about climate change, the world community’s responsibility to reduce our carbon footprint rests with each and every individual and organization. Responsible behavior is no longer an option – it’s a necessity. One simple way to improve sustainability in construction is to use more wood products.

So if, like us, you’re committed to playing your part in a sustainable future for our world, knowing how to identify sustainable wood will help you to make the right selections when looking for materials for your new wood flooring, cladding or decking.

As you can probably tell, this can be quite a complex matter. With the planet’s trees being harvested at a frightening rate, it’s about more than just the environmental features of the wood itself – and it’s our responsibility to make choices that protect the world’s forests.

There are many materials available for construction projects, each with its pros and cons, but none can claim to combine usefulness, availability, and sustainability as well as wood does. Here, we explore some environmental advantages that wood brings to the table.

Compared with competing building materials such as metal, plastics, stone, and concrete, wood offers a series of benefits – key among these is that it is a renewable resource – as a natural product, wood supplies can be renewed by planting new trees and sustainable forestry.

At Thermory, we strive to contribute to the sustainable management of forests, and there is a strong movement in this area by many timber manufacturers. At the end of its use as a construction material, wood can also be re-used, recycled, or downcycled.

The level of carbon emissions from wood production is less than 100 kg of CO2 per 1,000 kg produced, compared with over 300 kg for brick and over 2,000 kg for steel.

In addition, global studies assessing the lifecycle of building materials have found that wood is less damaging in terms of air and water pollution, solid waste, and the use of energy and ecological resources.

Wood’s lifetime embodied energy – the amount of energy consumed through the production process – is more than three times lower than that of steel, plastic, and concrete, all of which also require more effort and resources to dispose of at the end of their useful life.

Wood byproducts such as bark and shavings can additionally be used as a biofuel, offsetting energy used in the production process.

Wood that has been used in construction may still be milled and repurposed for other building or home improvement projects.

Even when it reaches the very end of its lifecycle though, wood doesn’t require a special process to return its nutrients to the earth – as long as it’s given suitable conditions, it will break down naturally itself, which also makes it ideal for composting.

By contrast, plastic can take up to 1,000 years to break down, and recycling or downcycling steel and concrete requires significant amounts of energy – albeit less than producing them as new from virgin materials.

As any other process, timber production demands resources, but it also offsets them in the long run. An average hardwood tree, such as alder or mahogany, will absorb around 22 kg of CO2 from the atmosphere per year, as well as other polluting gases including nitrogen oxides, ammonia, and sulfur dioxide.

The really great thing is that once the tree has been turned into wood for use as a building material, it locks the carbon dioxide away for the duration of its usage, which could be anything from a few decades to hundreds of years.

When working with restrictive regulatory requirements for sustainability, wood is an ideal building material that can help when it comes to gaining permissions for a project. Wood’s versatility and sustainability features can make it much easier to attain third-party certification.

Conforming to recognized standards for sustainability can give the building project a positive public image – and in some cases, it can be the difference between getting a contract or not in the first place.

Sustainable forest management means that woodlands are managed carefully and properly protected. This means that the forests are used in a way and at a rate that maintains their biodiversity, productivity, regeneration capacity, vitality and their potential to fulfil relevant ecological, economic and social functions in the long run, at local, national, and global levels. Sustainable forestry stands for not causing damage to other ecosystems or endangered species.

There are various global institutions involved in encouraging and supporting responsible forestry by setting out standards and certifying producers according to them. The best known of these are the Forestry Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC).

The Nordic Swan Ecolabel, which is used to certify environmentally friendly products, also lays out specific requirements for wood-based products covered by the label. Meanwhile, the European Union has introduced legal measures to protect EU forests by limiting annual harvests and setting out requirements for replacing felled trees, making buying European wood a sustainable choice as the region’s timber industry now plants more trees than it harvests.

Most Thermory products can be provided with FSC, PEFC or Nordic Swan Ecolabel certification, helping our customers ensure that they buy sustainable wood flooring, decking, cladding and wall panels.

Once wood has been harvested, it can be treated in various ways to preserve it, extend its lifespan and get it ready to use. If you’re familiar with Thermory, you’ll know that we’re all about thermal modification, which presents numerous benefits related to durability, dimensional stability, rot and pest resistance and safe and sustainable use and disposal.

The other option is chemical treatment, for example acetylation or furfurylation, where the wood is impregnated with certain chemicals, in some cases followed by additional steps such as heating. While these processes can offer sustainability benefits by enhancing the moisture and pest resistance, durability and dimensional stability of the wood, they also raise health and environmental concerns that can be avoided with the chemical-free thermal modification process.

As no chemicals are used in the thermal modification process, thermowood products are safe and there’s no need to handle them as hazardous waste after use.

With the urban population steadily growing and climate change becoming a pressing topic, cities have the challenge to offer high-quality, affordable and environmentally friendly housing.

Natural resources like wood are the only truly renewable building materials. As every new-grown m³ of wood binds a full ton of CO2, wood as such is not only climate-neutral, but climate-positive. The more wood we store (e.g. in buildings), the less CO2 the atmosphere needs to deal with.

For example, Powerhouse Telemark by Snøhetta is a co-working building in Porsgrunn, Norway designed to be carbon negative and produce more energy than it will consumer over a 60-year lifespan.

Timber is no new construction material. Various inspiring buildings from around the world show that this naturally sustainable material can be used in creating oustanding architecture.

Compared to steel or concrete, wood can support its own weight better, which allows for larger spaces and fewer necessary supports in building designs. Even high-rise buildings have been created with it. Wood is also good material for prefabrication of mayor construction elements. This leads to a high material and time efficiency, reduced waste and cost control.

With so many tree species available, architects can construct their vision as easily as when using artificial materials. For example, timber cladding products made from pine trees tend to have distinctive knots that reinforce the natural beauty of it. Wood cladding can be painted any color needed and variety of cladding profiles give plenty of options for designing a truly unique building.

Better yet, as an organic material, wood maintain a comfortable and healthy indoor climate. Studies have shown that environments with wooden structures have positive psychological and physical effects on humans.

Read more about the positive impact of wood on health and well-being

Advanced technologies in wood production allow to prevent and forget a lot of negative processes like twisting, cracking and decay. For example, during the thermal modification process, the wood’s density decreases and its structure changes, which gives thermowood many advantages.

Unlike chemical impregnation, thermal modification enhances the wood throughout, not just the outer surface, resulting in boards that are stable and durable in every sense.

With proper care, wooden houses can serve for hundreds of years and even after the material’s life as cladding, it can be reused for other use cases.

It can be tempting to go for a cheaper option, but as well as negatively affecting habitats and the longevity of the planet’s forests, supporting irresponsible forestry can damage neighbouring ecosystems, cause local environmental issues, increase carbon emissions, reduce levels of embodied carbon stored by trees and result in poor-quality wood products. Over the long term, these issues can be significantly damaging to the environment.

Buying wood that has been certified by one of the above organizations gives the reassurance that you aren’t at risk of contributing to these unwanted outcomes for both the planet and your own project. You’ll also know that the forests used are being responsibly managed, meaning the producers are replacing harvested trees.

A big part of the reason we’re so passionate about this strong, elegant natural material is that when it comes to sustainability, the benefits speak for themselves. Because Thermory’s specialized thermal modification process doesn’t require any chemical processes, our wood is highly durable, providing strength and stability that stand the test of time.

Wood is a superb construction material – and alongside its versatility, aesthetics, and insulating properties, the environmental advantages over the alternatives only strengthen this claim.

The Thermory Design Awards 2025 once again shine a spotlight on the most inspiring uses of thermally modified wood in architecture and design. This year’s...

When it comes to decking, there are many options from natural wood to plastics and everything in between. It’s no secret that we at Thermory prefer...

Yes — and you absolutely should. Mixing cladding...

When designing...

...

Shiplap cladding...

Looking to create a poolside space that’s as durable as it is beautiful? Thermo-ash decking is the perfect choice for stylish, low-maintenance outdoor...

The most...

Rooftop spaces...

Contemporary...

Wood decking adds...

While a wood species’ natural properties play an important role in determining the timber cladding’s durability, they’re only part of the...

From minimal forest cabins to bold urban residences, black timber cladding has emerged as a defining element of modern architectural design. Its striking,...

As the construction and design industries evolve, so does the demand for sustainable, high-performance building materials. For over 25 years, Thermory has...

Picture a wood that balances elegance, durability and versatility – a natural material that not only meets your demands but also exceeds your...

Combining different wood species, finishes and profiles brings variety to any interior or exterior design, delivering a tantalizing injection of texture and...

We were curious about the architecture trends and the popularity of timber in Australia, so we asked our down under partner, McCormacks Australia, to tell...

The eye-catching black Thermory Ignite cladding provides a bold look, while also offering the stability and durability that Thermory is known...

With the EU, US and many other countries aiming to achieve carbon neutrality by 2050, sustainability is not just a construction trend anymore, but it’s...

In the quest to shift our world towards more sustainable practices and circular processes, designers are increasingly turning their attention to...

Sometimes, the best place to unwind and get away from it all is a secluded forest cabin in breathtaking surroundings. Find inspiration for your next...

When it comes to designing and constructing educational spaces, choosing the right materials is crucial. There has been a growing trend towards...

As architects and landscape designers, creating indoor outdoor living spaces that are sustainable and eco-friendly is more important than ever. With a...

Wood is a highly valuable material and although it grows abundantly, we must treat this natural resource with respect and create value from even the smaller...

From intimate spaces like our homes to public urban areas, the environment surrounding us has a big effect on our well-being. Recent turbulent years have...

Finding the best solution to clad buildings is important for several reasons – as well as defining the look and feel of your design, it also has a major...

Shou sugi ban, or yakisugi, is an ancient Japanese art of treating wood with a flame to make it more waterproof and rot resistant. Thermory’s Ignite range...

Thermory Design Awards is part of Thermory 25 celebrations for acknowledging and rewarding our...

Curators of Tallinn Architecture Biennale 2022 exhibition “Edible ; Or, The Architecture of Metabolism”, Lydia Kallipoliti & Areti...

The aim of biophilic design is to create buildings and spaces that enable harmonious, naturally enjoyable experiences for their users by promoting the...

The purpose of biophilic design is to create spaces that deliver benefits for both human health and the environment by nurturing people’s innate affinity...

Introduce comfort, style and practicality into your outdoor space so that you can enjoy more time in the fresh air during the coming warmer...

Summer is just around the corner, and as we eagerly look out to see the evidence of rising temperatures, that can only mean one thing...

Natural wood can be used in many different ways. The beauty and versatility make wood unequalled building material. As both an interior and exterior design...

When it comes to...

Home is where the heart is – a place where the whole family can feel safe and warm. The building materials you choose should enhance this feeling and...

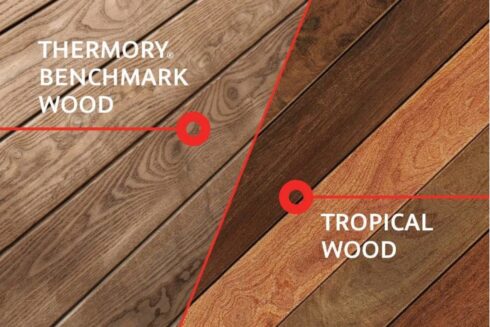

For decades, tropical hardwoods have been prized for their density, durability, and rich appearance. But their popularity comes at a high cost. Many of...

...

Thermally modified wood, often referred to as thermowood, is real wood enhanced using only heat and steam to improve its durability, dimensional stability,...

Thermally modified wood offers a unique combination of beauty, durability, and versatility. If you’re searching for fresh exterior cladding ideas,...

Wood is a natural material – and that’s part of its magic. Over time, its appearance changes, especially when exposed to the elements. Thermory’s...

You’ve selected the perfect decking for your outdoor space – now you just need to decide how best to secure it in its chosen location. There are two...

Great design is more than just aesthetics—it’s about how a space makes you feel. Increasingly, research confirms what many have intuitively known: wood...

Ensuring the highest quality with the smallest possible ecological footprint and responsible use of resources are all principles that we consider important...

Throughout the history of architecture, surely no other material has been as influential as wood. It’s rare to see a building that’s been produced...

When considering how you’ll lay your new deck, there are many more options to decide between than simple vertical or horizontal alignment. In fact, with a...

A trend is taking root in the worlds of architecture and interior design based on using natural materials and living plants to better...

If you’re considering which wood types to use for a renovation or construction project, there are several considerations that may influence your decision...

The wood-paneled interiors so common to mid-century homes have become sought after again, as many seek the warm, cozy feeling that the natural material...

The warmth of springtime is fast approaching, and our thoughts are naturally turning towards spending more time outside. If you have a wooden terrace or...

PaCS (Press and Click System) product ranges combine high-quality Thermory thermowood with the unique installation system by Grad. It is a popular hidden...

To ensure that your Thermory cladding retains its natural warm and authentic character, it’s important to apply the correct maintenance techniques. The...

No matter where you live when you’re choosing a decking or cladding material, you’ll have to be mindful of how that material will change over time...

The tiny house movement has gained more momentum in the last decade, but why? It is based on tiny living: owning less so that what you own doesn’t own...

Real wood cladding has many functional benefits as well as a charming aesthetic. But if you are looking to make a bolder statement...

In 2022, the global megatrend of sustainable architecture and building practices will continue. Architecture trends influence the choice of materials both...

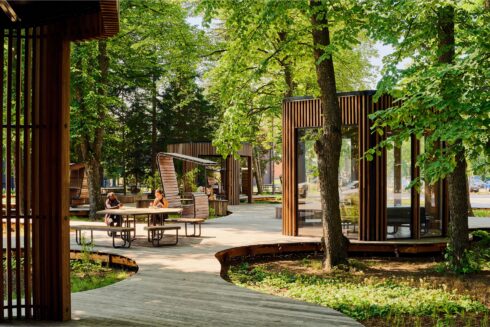

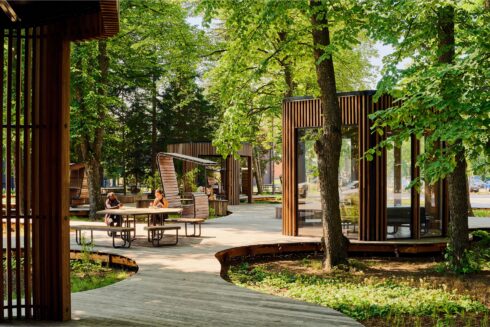

THERMORY BENCHMARK THERMO-ASH

ESTONIA

THERMORY BENCHMARK THERMO-PINE

GEORGIA, USA

THERMORY THERMO-ASH DECKING, THERMO-SPRUCE CEILINGS AND COATED CLADDING

OREGON, USA

BENCHMARK THERMO-PINE CLADDING C4 20x115 / 26x 115, DECKING D4 26x115

ESTONIA

BENCHMARK THERMO-PINE

POLAND

BENCHMARK THERMO-PINE

LITHUANIA

KODIAK THERMO-SPRUCE

MICHIGAN, USA

THERMORY THERMO-PINE MIX & MATCH CLADDING

NORWAY

THERMORY BENCHMARK THERMO-SPRUCE BRUSHED CLADDING, THERMO-ASH DECKING AND FLOORING

ESTONIA

THERMORY BENCHMARK THERMO-PINE CLADDING C4

NORWAY

THERMORY BENCHMARK THERMO-PINE CLADDING AND ROOFING

POLAND

THERMORY BENCHMARK THERMO-RADIATA PINE CLADDING C3

NEW ZEALAND

THERMORY DRIFT THERMO-SPRUCE CLADDING

TEXAS, USA

THERMORY BENCHMARK THERMO-PINE CLADDING C3 20X115 MM, ROOFING C10 20X140 MM AND DECKING D4 SG 26X140

NORWAY

THERMORY BENCHMARK THERMO-PINE CLADDING C8 26X140 MM

NEW ZEALAND

THERMORY BENCHMARK THERMO-ASH DECKING D31

CANADA

THERMORY BENCHMARK THERMO-ASH AND THERMORY SHINGLES WALL PANELLING

ESTONIA

THERMORY BENCHMARK THERMO-ASH CLADDING C5 20X72/140/190MM, BRUSHED AND THERMO-ASH MEDIUM FLOORING F5 18X245

ESTONIA