To ensure that your Thermory cladding retains its natural warm and authentic character, it’s important to apply the correct maintenance techniques. The warm, dry conditions of summer make this the best time of year to carry out any maintenance, so we’ve put together a handy guide to help you keep your cladding in good condition and looking its best for years to come.

Thermal modification enriches the natural tone of wood as well as enhances its durability and stability, making it perfect for both indoor and outdoor use. Proper installation and good maintenance will help you get the most out of your cladding, so remember to follow the instructions that come with your Thermory products!

Like any wood product, thermowood will change color when exposed to sunlight and the weather. This a natural process that doesn’t affect the durability of the material. Over time, unpainted Thermory boards will age to a beautiful silver-gray shade with some light cracking on the surface. This aging process starts as soon as the boards are installed and can take anything from a few months to a few years depending on the intensity of the sun and the weather conditions.

If you have Thermory cladding boards installed indoors, you’ll get to enjoy the beautiful deep wood tones for decades. And looking after them couldn’t be simpler – whenever they need a little TLC, use a clean cloth to wipe off any dirt or dust or wash down with water and a soft brush. For outdoor cladding, you should look to clean the boards at least once a year. If you find that they’re getting particularly dirty or mossy you can, of course, clean them more often – but an annual clean should usually be enough to keep them in top condition.

As with indoor cladding, cleaning Thermory boards that have been installed outdoors is pretty straightforward. Start by scrubbing off any dirt, moss and debris with water and a soft brush. Once this is done, clean the boards with a dedicated wood cleaner and warm water and then rinse. When it comes to rinsing, keep in mind that strong jets of water can damage the wood’s surface, so we recommend that you avoid using a pressure washer. Instead, rinse your cladding with a garden hose using a spray tip on a low-pressure setting.

At Thermory, we don’t use any chemicals in the production of our thermally modified wood, and all of our products are made with the environment in mind. For this reason, we recommend avoiding solvent-based products when carrying out maintenance on your Thermory cladding boards. Water-based alternatives are much more environmentally friendly and there are many products available for you to choose from.

If you’ve installed uncoated cladding boards, there are a few ways to minimize any cracking and color changes, and wood that has faded over time can also be restored to its natural shade. If you prefer, you have the option to change the color of the wood too. To slow the color-fading process, protect your Thermory boards with a UV-resistant pigmented finish such as a wax, stain, paint or mineral oil. However, remember to steer clear of organic oils as they can be a food source for bacteria and mold.

If you want to delay cracking while still allowing the wood to gray, finish it with a colorless oil. Alternatively, if you have a specific shade in mind for your Thermory cladding, apply a UV-resistant wood preservative tinted with your desired color. Finally, if you’re thinking of painting your Thermory cladding with a solid color, choose a paint that’s suitable for use with thermally modified wood – there is a range of products available on the market. In all cases, remember to apply your finish to a clean, dust-free surface and always follow the manufacturer’s instructions.

If you’re looking to apply a fresh finish to oiled Thermory cladding boards, we recommend using a product that matches the original shade. The oil coating will usually last between one and three years, depending on the weather, so you should replenish at least once every three years. However, if the wood surface starts to look worn or uneven before then, you can choose to refinish the boards sooner.

Before applying paint or oil to cladding boards, the surface must be clean, dry and free of dust, so start by removing any loose paint, dirt and other debris with warm water and a scrubbing brush, then leave them to dry thoroughly. If applying paint or a tinted oil product, give it a good mix and test it on a small area first before applying it to the rest of the façade. Apply the finish on the cladding boards using the tools and application methods recommended by the manufacturer. Remember that drying times will vary from product to product, so it’s important to follow the suggested waiting times before applying an additional coat.

The maintenance schedules for coated Thermory cladding will depend on the type of board you have installed. Drift and Vivid Silvered boards don’t require any additional finishing – the coatings on these products are designed to harmonize with the wood’s aging process until it reaches a beautiful silver-gray finish.

For Vivid Translucent 7 boards, touch up the finish when the surface starts to look worn or uneven, and at least once every seven years, using a translucent water-based paint that matches the tone you’re looking to achieve for your façade.

If you’ve installed Thermory Ignite boards, you’ll no doubt be keen to maintain that unique charred look. To do this, replenish the finish when the surface starts to look worn or uneven – at least every five years for Ignite 5 boards using a water-based, semi-translucent black paint, and at least every seven years with a water-based, opaque RAL9005 paint for Ignite 7.

Vivid Opaque boards should be refinished with a water-based opaque paint whenever the wood surface starts to look worn or uneven – at least every 10 years for Vivid Opaque 10 boards and every 15 years for Vivid Opaque 15 boards.

We hope you’ve found this guide useful. You can refer back to it any time for an overview on how to keep your cladding boards looking good as new, giving your façade that authentic warmth that only wood can bring, for years to come.

The Thermory Design Awards 2025 once again shine a spotlight on the most inspiring uses of thermally modified wood in architecture and design. This year’s...

Yes — and you absolutely should. Mixing cladding...

When designing...

...

Shiplap cladding...

The most...

Contemporary...

While a wood species’ natural properties play an important role in determining the timber cladding’s durability, they’re only part of the...

From minimal forest cabins to bold urban residences, black timber cladding has emerged as a defining element of modern architectural design. Its striking,...

As the construction and design industries evolve, so does the demand for sustainable, high-performance building materials. For over 25 years, Thermory has...

Picture a wood that balances elegance, durability and versatility – a natural material that not only meets your demands but also exceeds your...

Combining different wood species, finishes and profiles brings variety to any interior or exterior design, delivering a tantalizing injection of texture and...

We were curious about the architecture trends and the popularity of timber in Australia, so we asked our down under partner, McCormacks Australia, to tell...

With the EU, US and many other countries aiming to achieve carbon neutrality by 2050, sustainability is not just a construction trend anymore, but it’s...

In the quest to shift our world towards more sustainable practices and circular processes, designers are increasingly turning their attention to...

Sometimes, the best place to unwind and get away from it all is a secluded forest cabin in breathtaking surroundings. Find inspiration for your next...

When it comes to designing and constructing educational spaces, choosing the right materials is crucial. There has been a growing trend towards...

As architects and landscape designers, creating indoor outdoor living spaces that are sustainable and eco-friendly is more important than ever. With a...

Wood is a highly valuable material and although it grows abundantly, we must treat this natural resource with respect and create value from even the smaller...

From intimate spaces like our homes to public urban areas, the environment surrounding us has a big effect on our well-being. Recent turbulent years have...

Finding the best solution to clad buildings is important for several reasons – as well as defining the look and feel of your design, it also has a major...

Thermory Design Awards is part of Thermory 25 celebrations for acknowledging and rewarding our...

Curators of Tallinn Architecture Biennale 2022 exhibition “Edible ; Or, The Architecture of Metabolism”, Lydia Kallipoliti & Areti...

The aim of biophilic design is to create buildings and spaces that enable harmonious, naturally enjoyable experiences for their users by promoting the...

The purpose of biophilic design is to create spaces that deliver benefits for both human health and the environment by nurturing people’s innate affinity...

Natural wood can be used in many different ways. The beauty and versatility make wood unequalled building material. As both an interior and exterior design...

When it comes to...

Home is where the heart is – a place where the whole family can feel safe and warm. The building materials you choose should enhance this feeling and...

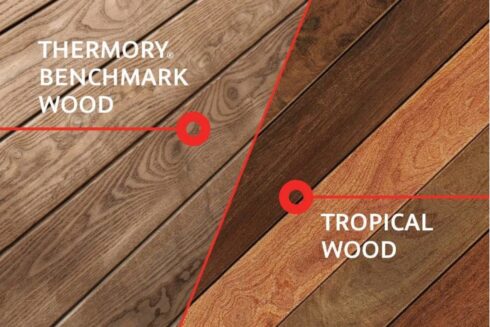

For decades, tropical hardwoods have been prized for their density, durability, and rich appearance. But their popularity comes at a high cost. Many of...

Thermally modified wood, often referred to as thermowood, is real wood enhanced using only heat and steam to improve its durability, dimensional stability,...

Thermally modified wood offers a unique combination of beauty, durability, and versatility. If you’re searching for fresh exterior cladding ideas,...

With rising concerns about climate change, the world community’s responsibility to reduce our carbon footprint rests with each and every individual and...

Wood is a natural material – and that’s part of its magic. Over time, its appearance changes, especially when exposed to the elements. Thermory’s...

Great design is more than just aesthetics—it’s about how a space makes you feel. Increasingly, research confirms what many have intuitively known: wood...

Ensuring the highest quality with the smallest possible ecological footprint and responsible use of resources are all principles that we consider important...

Throughout the history of architecture, surely no other material has been as influential as wood. It’s rare to see a building that’s been produced...

A trend is taking root in the worlds of architecture and interior design based on using natural materials and living plants to better...

If you’re considering which wood types to use for a renovation or construction project, there are several considerations that may influence your decision...

The wood-paneled interiors so common to mid-century homes have become sought after again, as many seek the warm, cozy feeling that the natural material...

No matter where you live when you’re choosing a decking or cladding material, you’ll have to be mindful of how that material will change over time...

The tiny house movement has gained more momentum in the last decade, but why? It is based on tiny living: owning less so that what you own doesn’t own...

Real wood cladding has many functional benefits as well as a charming aesthetic. But if you are looking to make a bolder statement...

In 2022, the global megatrend of sustainable architecture and building practices will continue. Architecture trends influence the choice of materials both...

THERMORY BENCHMARK THERMO-PINE

GEORGIA, USA

THERMORY THERMO-ASH DECKING, THERMO-SPRUCE CEILINGS AND COATED CLADDING

OREGON, USA

BENCHMARK THERMO-PINE CLADDING C4 20x115 / 26x 115, DECKING D4 26x115

ESTONIA

BENCHMARK THERMO-PINE

POLAND

BENCHMARK THERMO-PINE

LITHUANIA

THERMORY THERMO-PINE MIX & MATCH CLADDING

NORWAY

THERMORY BENCHMARK THERMO-SPRUCE BRUSHED CLADDING, THERMO-ASH DECKING AND FLOORING

ESTONIA

THERMORY BENCHMARK THERMO-PINE CLADDING C4

NORWAY

THERMORY BENCHMARK THERMO-PINE CLADDING AND ROOFING

POLAND

THERMORY BENCHMARK THERMO-RADIATA PINE CLADDING C3

NEW ZEALAND

THERMORY BENCHMARK THERMO-PINE CLADDING C3 20X115 MM, ROOFING C10 20X140 MM AND DECKING D4 SG 26X140

NORWAY

THERMORY BENCHMARK THERMO-PINE CLADDING C8 26X140 MM

NEW ZEALAND

THERMORY BENCHMARK THERMO-ASH CLADDING C5 20X72/140/190MM, BRUSHED AND THERMO-ASH MEDIUM FLOORING F5 18X245

ESTONIA