Our decking boards undergo intense thermal modification, giving them unrivaled durability and stability running all the way through to the core. Each board is naturally beautiful, expertly modified and highly functional – the perfect blend of art and science.

Thermowood decking is easy to install and provide the long-lasting comfort and visual appeal that Thermory products are so well known for. We offer a variety of durable outdoor decking solutions, including modular systems and boards with a broad selection of widths and profiles. Expand your living space outdoors and move one step closer to nature.

THERMO-ASH

YOUR UNEQUALLED CHOICE FOR HARDWOOD DECKING

With its smooth finish and its rich, dark color, thermally modified ash is an exceptionally high-value wood

Thermo-ash boasts an aesthetically pleasing look and feel with a clean surface

Offering superior dimensional stability and the highest possible durability class, our thermo-ash retains rot resistance for 25+ years when installed and maintained according to Thermory’s guides

With its low moisture absorption, thermo-ash twists, cups and bends less than untreated wood in outdoor use, with less shrinkage and expansion

As a non-toxic, natural material, thermally modified ash is more environmentally friendly than tropical hardwoods and man-made alternatives

Thermo-ash decking doesn’t accumulate heat and feels pleasant underfoot

Thermo-ash decking is easy to maintain and comes with simple installation options

FSC-certified ash is available upon request

smooth

Benchmark – natural thermally modified wood; optional oil finishing

Herringbone – natural thermally modified ash in a herringbone pattern

QuickDeck – natural thermally modified ash in modular decking tiles

Flow – natural thermally modified ash in curved design boards

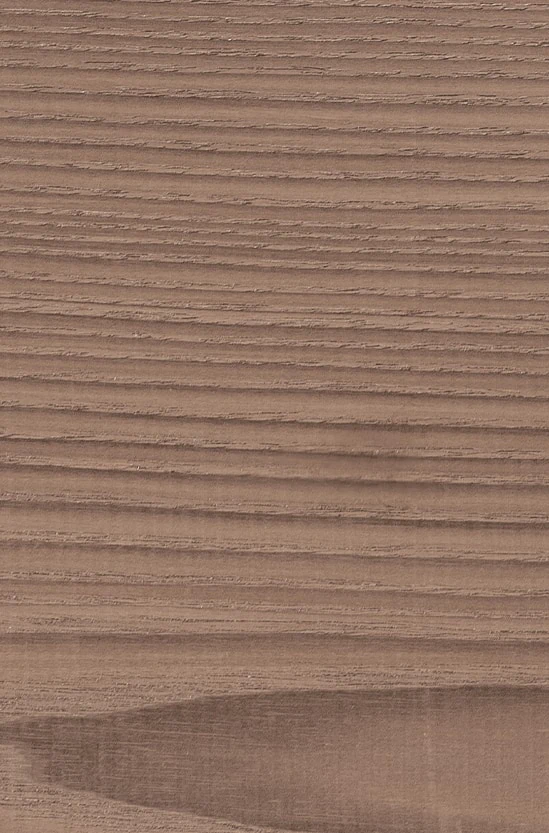

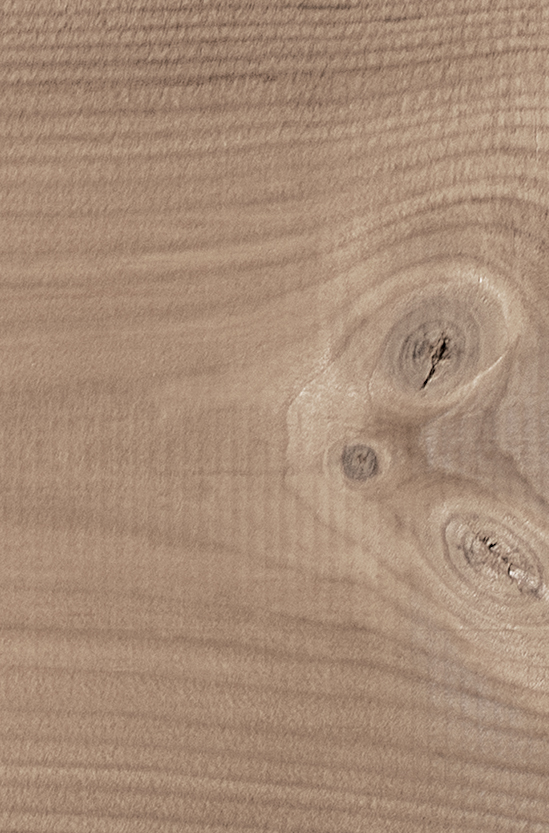

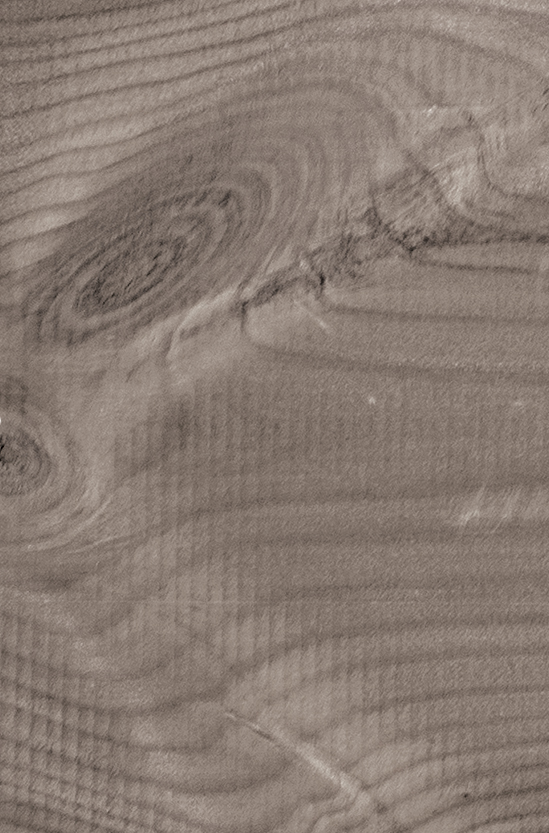

Wood aging in outdoor conditions:

After production

1 year

5-20 years

As a natural material wood ages unevenly, so the sides of decking will discolor at different rates depending on weather exposure. We have developed a series of wood finishing options to help you achieve a consistent result and avoid uneven graying.

THERMO-PINE

THE NEW DURABILITY STANDARD FOR SOFTWOOD DECKING

Thermal modification makes the pine more durable and stable while emphasizing its characteristic knotted pattern – all without any chemicals

Thermally modified pine has an attractive rich golden-brown color

Thermo-pine decking is a natural, durable and environmentally friendly choice

With its low moisture absorption, thermo-pine twists, cups and bends less than untreated wood in outdoor use, with less shrinkage and expansion

We source only Nordic pine, which is highly valued for its mechanical properties

We offer thermo-pine decking with the Nordic Swan Ecolabel

smooth

Benchmark – natural thermally modified wood; optional oil finishing

Wood aging in outdoor conditions

After production

1 year

5-20 years

As a natural material wood ages unevenly, so the sides of decking will discolor at different rates depending on weather exposure. We have developed a series of wood finishing options to help you achieve a consistent result and avoid uneven graying.

THERMO-SPRUCE

DURABLE SOFTWOOD DECKING WITH NATURAL CHARM

Thermory’s thermally modified spruce is a softwood solution that offers exceptional rot resistance and longevity

Our thermo-spruce decking range creates a gives your facade a naturally charming appearance with beautiful visible knots

The decking is available with extra-wide boards that showcase thermo-spruce’s impressive stability and enable quick installation with fewer visible gaps

With its low moisture absorption, thermo-spruce twists, cups and bends less than untreated wood in outdoor use, with less shrinkage and expansion

Thermo-spruce is an affordable decking material that’s perfect for demanding climatic conditions

We offer thermo-spruce decking with the Nordic Swan Ecolabel

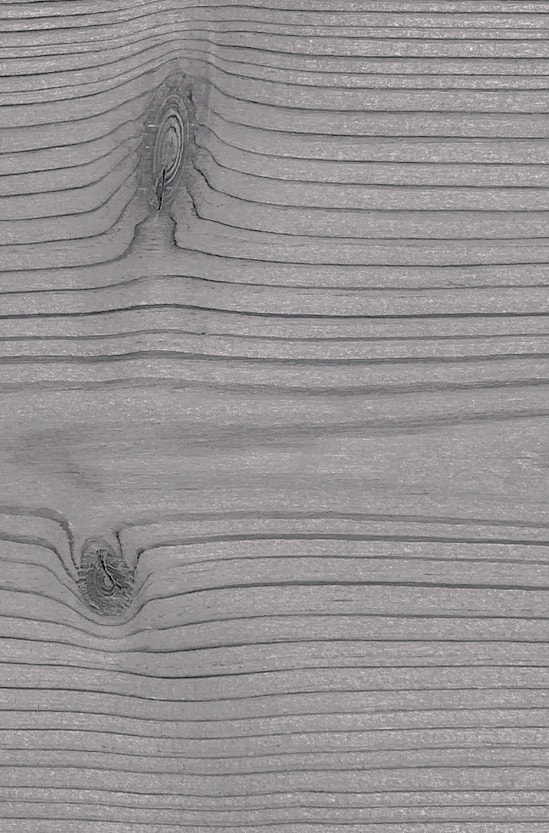

Wood aging in outdoor conditions

After production

1 year

5-20 years

As a natural material wood ages unevenly, so the sides of decking will discolor at different rates depending on weather exposure. We have developed a series of wood finishing options to help you achieve a consistent result and avoid uneven graying.

Not sure? Contact us and lets find you a perfect product

We operate in 98 countries all over the world.